In modern households, gas appliances such as boilers and stoves play a crucial role in providing essential services. These devices rely on ignition systems to initiate combustion, ensuring efficient operation and optimal performance. However, over time, these ignition systems may experience wear and tear due to various factors like dust accumulation or component degradation. As a result, it becomes imperative for homeowners and maintenance professionals alike to prioritize regular maintenance of the ignition system to ensure safe and reliable functioning.

Consider the case of Mr. Johnson, who recently experienced an unexpected malfunction with his gas stove’s ignition system. One evening while preparing dinner for his family, he encountered difficulty in igniting the burners despite repeatedly turning the knob to the “ignite” position. Frustrated by this sudden issue, Mr. Johnson contacted a professional technician who diagnosed the problem – a faulty spark module within the stove’s ignition system. This incident highlights not only the importance of maintaining gas appliance ignition systems but also emphasizes the potential consequences that can arise from neglecting their upkeep.

To prevent similar situations and ensure uninterrupted functionality, this article explores key aspects of ignition system maintenance for gas appliances like boilers and stoves. By delving into common issues that arise with these systems and discussing recommended practices for their care, readers will be equipped with the knowledge and understanding to effectively maintain their gas appliance ignition systems.

One common issue that can occur with gas appliance ignition systems is a buildup of dirt and debris, which can hinder the spark or pilot light from igniting. Regular cleaning of the ignition components, such as the electrodes and burner ports, is crucial to prevent this problem. Using a soft brush or cloth, gently remove any dust or residue that may have accumulated. Avoid using abrasive materials or chemicals that could damage the components.

Another potential issue is wear and tear of the ignition components over time. This can result in weak sparks or inconsistent ignition. In such cases, it may be necessary to replace faulty parts like the spark module or igniter electrode. It’s recommended to consult the appliance’s user manual or seek professional assistance for proper identification and replacement of these components.

Additionally, ensuring proper alignment of the ignition system is essential for optimal performance. Misalignment can cause issues like delayed ignition or uneven flame patterns. Carefully inspect the placement of the electrodes relative to the burner ports and make necessary adjustments if needed. Again, referring to the user manual or seeking professional help can provide guidance on correct alignment procedures.

Regular maintenance also involves checking for gas leaks around the ignition system area. A distinct smell of gas or hissing sounds could indicate a leak, which should be addressed immediately by turning off the gas supply and contacting a qualified technician.

Lastly, proactive measures like scheduling periodic inspections by professionals can greatly contribute to maintaining a safe and efficient ignition system. These experts have specialized knowledge and tools to assess complex issues that may not be easily identifiable by homeowners alone.

In conclusion, regular maintenance of gas appliance ignition systems is crucial for their safe and reliable operation. By following recommended practices such as cleaning, replacing faulty parts, aligning components correctly, checking for gas leaks, and seeking professional assistance when needed, homeowners can ensure uninterrupted functionality while minimizing risks associated with malfunctioning ignition systems.

Understanding the Ignition System

Imagine coming home on a chilly winter evening, looking forward to heating up your cozy living room with a gas fireplace. You turn the ignition switch, but nothing happens. Frustrating, isn’t it? This scenario highlights the essential role of a well-maintained ignition system in our daily lives. In this section, we will delve into the intricacies of gas appliances’ ignition systems, including boilers and stoves.

Key Components and Functionality:

To comprehend how an ignition system works, it is crucial to familiarize ourselves with its key components. The main elements typically found in gas appliance ignition systems include the pilot light or electronic igniter, flame sensors, control module or circuit board, and safety devices like pressure switches. These components work together seamlessly to ensure successful combustion by reliably igniting fuel sources such as natural gas or propane.

Maintaining an optimal functioning ignition system is vital for several reasons. Firstly, it enhances energy efficiency by ensuring that fuel consumption aligns with actual heat output. Secondly, regular maintenance minimizes safety risks associated with malfunctioning or failed ignitions. Lastly, a well-maintained ignition system extends the lifespan of gas appliances while reducing costly repairs or replacements.

Benefits of Proper Ignition System Maintenance:

Proper maintenance practices can significantly contribute to prolonging the life and performance of gas appliances. Consider these benefits that stem from regularly maintaining your equipment’s ignition system:

- Enhanced Safety: A well-functioning ignition system reduces the risk of dangerous situations such as explosions or carbon monoxide leaks.

- Energy Efficiency: By optimizing combustion processes through proper maintenance procedures, you can maximize energy efficiency and reduce overall utility costs.

- Consistent Performance: Regularly servicing your ignition system ensures consistent performance over time.

- Cost Savings: Preventive maintenance helps identify potential issues early on before they develop into major problems that require expensive repairs.

By understanding the significance of maintaining an efficient ignition system, we can ensure safe and reliable operation of our gas appliances.

Next Section: Common Ignition System Issues

Common Ignition System Issues

Understanding the Ignition System of gas appliances, boilers, and stoves is crucial to ensuring their efficient operation. Now let’s delve further into common ignition system issues that can arise and how to address them effectively.

Imagine a scenario where you wake up on a chilly morning looking forward to a warm cup of coffee brewed by your trusty gas-powered stove. However, upon turning it on, you notice that there is no flame or spark igniting the burner. This situation highlights one possible issue with an ignition system – lack of proper spark generation.

To maintain an optimal functioning ignition system, consider the following key maintenance tips:

- Regular Inspection: Conduct periodic visual inspections to check for any signs of wear or damage in the ignition components.

- Cleaning: Remove dirt, dust, and debris from the ignition system using compressed air or a soft brush.

- Electrode Adjustment: Ensure proper electrode alignment according to manufacturer specifications.

- Component Replacement: Replace faulty or worn-out parts promptly to prevent potential failures.

By adhering to these maintenance practices, you can minimize the risk of encountering problems with your gas appliances’ ignition systems.

In addition to regular maintenance efforts, understanding some common issues related to the ignition system can help troubleshoot any anomalies more efficiently. The table below outlines four typical problems along with their potential causes and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| No Spark | Faulty Igniter | Replace igniter |

| Weak Spark | Dirty Electrodes | Clean electrodes |

| Delayed Ignition | Clogged Burner Ports | Clear blockages |

| Intermittent Ignitions | Loose Connections | Tighten connections |

These troubleshooting steps can assist in identifying and resolving various malfunctions within gas appliance ignition systems, ensuring optimal performance and safety.

Moving forward to the next section, we will explore the signs of ignition system problems. It is essential to recognize these indicators early on to prevent potential hazards and address issues promptly.

Signs of Ignition System Problems

Imagine this scenario: You wake up on a cold winter morning, eager to start your day with a warm cup of coffee. However, when you try to turn on your gas stove, nothing happens. Frustrated and shivering, you realize that there might be an issue with the ignition system. This example highlights the importance of being aware of signs indicating potential problems in gas appliances, boilers, and stoves’ ignition systems.

Signs of Ignition System Problems:

-

Inconsistent or Delayed Ignition:

- Gas appliances that exhibit inconsistent or delayed ignition can indicate underlying issues within the ignition system.

- For instance, if your boiler takes longer than usual to ignite or if flames are not consistent in size and strength throughout its operation, it may signify an ignition problem.

-

Sooty or Discolored Flames:

- Pay attention to the color and appearance of the flame produced by your gas appliance’s burner.

- If you notice soot buildup or discoloration in the flame (e.g., yellow or orange instead of blue), it could be indicative of incomplete combustion due to ignition system malfunctions.

-

Unusual Smells:

- A faulty ignition system can result in unburned gas escaping into your living space.

- If you detect a persistent odor resembling rotten eggs or sulfur near your gas appliance, it is crucial to address this promptly as it may pose a safety risk.

-

Frequent Pilot Light Outages:

- The pilot light serves as an indicator of overall system functionality.

- Should you experience frequent pilot light outages without any apparent cause (such as drafts extinguishing the flame), it suggests potential issues with your appliance’s ignition system.

- Safety concerns associated with malfunctioning ignition systems

- Potential hazards posed by escaped natural gas

- The inconvenience and discomfort caused by unreliable ignition systems

- Financial implications of repairs or replacements resulting from neglected ignition system issues

Emotional Table:

| Emotional Impact | Ignition System Problems |

|---|---|

| Safety | Escaped natural gas |

| Comfort | Inconsistent warmth |

| Peace of Mind | Reliable operation |

| Financial Consequences | Costly repairs |

Importance of Regular Inspections

As homeowners, it is crucial to understand the signs that may indicate problems with our gas appliances’ ignition systems. By observing these warning signals promptly, we can take necessary measures to ensure safety, comfort, and peace of mind in our homes. Consequently, regular inspections become imperative to prevent potential hazards and costly repairs associated with faulty ignition systems.

Importance of Regular Inspections

To ensure the safe and efficient operation of gas appliances, boilers, and stoves, regular inspections of their ignition systems are crucial. Ignition system problems can lead to malfunctioning equipment, increased energy consumption, and even potential safety hazards. By conducting routine inspections, these issues can be identified early on and addressed promptly. This section will highlight the importance of regular inspections by exploring a hypothetical case study and providing an overview of common benefits.

Case Study:

Imagine a scenario where a homeowner neglects regular inspections for their gas boiler’s ignition system. Over time, the performance of the ignition system begins to deteriorate unnoticed. Eventually, the boiler fails to ignite consistently, resulting in inconsistent heating during cold winter months. As a consequence, comfort levels within the household decrease significantly while energy bills soar due to longer operating periods required to maintain desired temperatures.

Benefits of Regular Inspections:

Regular inspections offer numerous advantages that contribute to both safety and cost-efficiency aspects associated with gas appliances’ ignition systems. Consider the following benefits:

- Early Detection: Timely inspection helps identify potential issues before they escalate into major problems.

- Enhanced Safety: Ensuring proper functioning of ignition systems minimizes risks related to gas leaks or fire hazards.

- Improved Energy Efficiency: Well-maintained ignition systems operate more efficiently, reducing overall energy consumption.

- Prolonged Equipment Lifespan: Routine inspections prevent premature wear and tear of components, extending the lifespan of gas appliances.

Table – Cost Comparison between Regular Inspections vs. Neglected Maintenance:

| Regular Inspections | Neglected Maintenance | |

|---|---|---|

| Upfront Costs | Low | High |

| Operating Costs | Reduced | Increased |

| Repairs | Minimal/Preventive | Extensive/Costly |

| Longevity | Extended | Reduced |

Regular inspections not only save homeowners from costly repairs but also contribute to a safer living environment and increased energy efficiency. Neglecting maintenance can result in more expensive repairs, higher operating costs, and shorter equipment lifespans.

Understanding the importance of regular inspections is just one step towards ensuring the optimal performance of gas appliances’ ignition systems.

Steps to Clean and Maintain the Ignition System

Having understood the importance of regular inspections for gas appliances, boilers, and stoves, let us now delve into the steps required to clean and maintain their ignition systems.

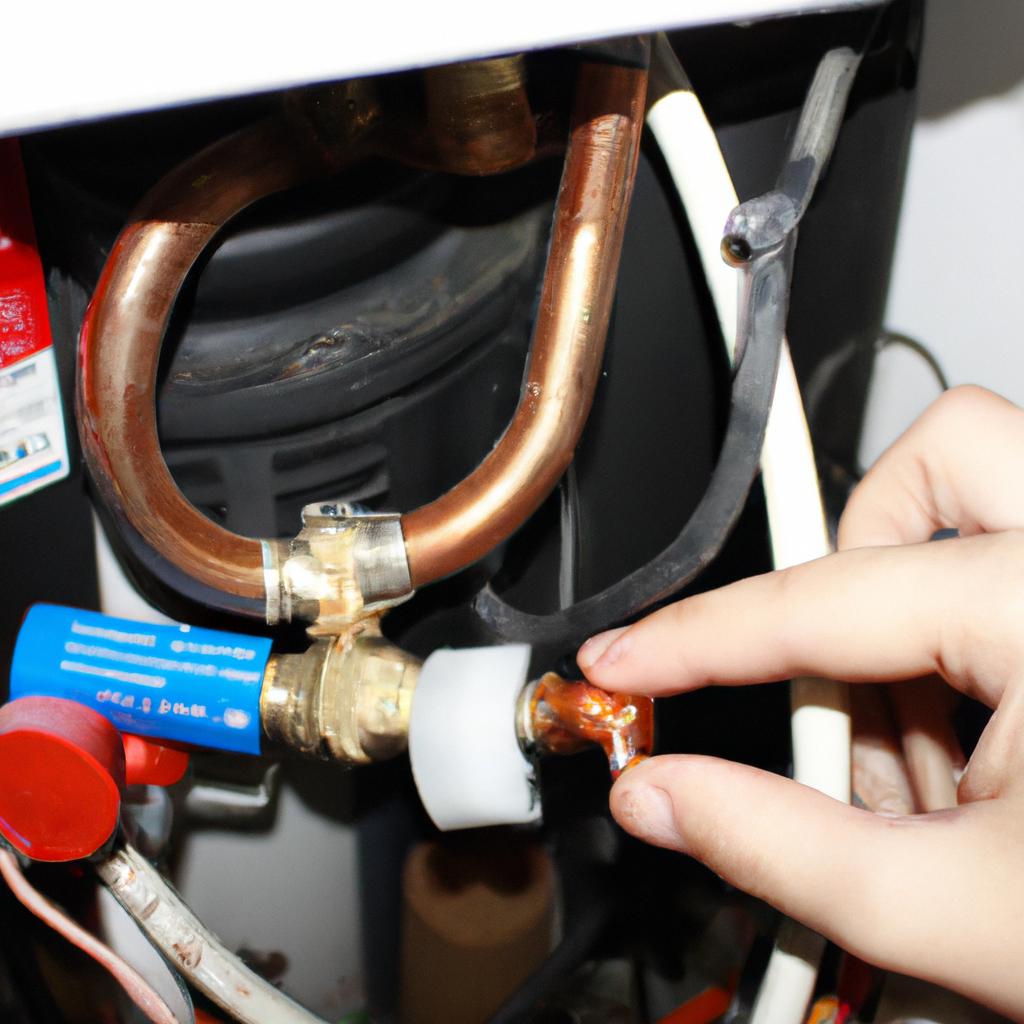

To illustrate these steps, consider a hypothetical scenario where an individual notices that their gas stove’s ignition system is not functioning properly. The igniter sparks weakly or fails to spark altogether when attempting to light the burner. In such cases, it becomes crucial to follow these steps:

-

Disconnect Power Supply:

Before cleaning or performing any maintenance on the ignition system, always ensure that the power supply is disconnected. This step minimizes the risk of electric shock or accidental activation of the appliance during maintenance. -

Remove Debris and Residue:

Begin by gently removing any visible debris or residue around the ignition system components using a soft brush or cloth. Pay close attention to areas surrounding the electrodes and burners as they are prone to collecting dirt or grease over time. -

Check Electrode Alignment:

Inspect the alignment of the electrodes in relation to the burners. Misalignment can hinder proper sparking and result in inefficient combustion. Adjust them if necessary so that they are positioned correctly—typically about ¼ inch above each burner. -

Test Sparking Functionality:

After completing the cleaning process, reconnect power supply temporarily (if safe) and test whether all burners produce consistent sparks when turned on manually. If there are still issues with sparking, it may be necessary to replace faulty components or seek professional assistance for further troubleshooting.

The following bullet point list outlines some key factors to keep in mind while maintaining your gas appliances’ ignition systems:

- Regular inspection helps identify potential issues early.

- Cleaning prevents blockages caused by debris accumulation.

- Proper electrode alignment ensures efficient sparking.

- Timely replacement of faulty components improves overall performance.

Markdown Table:

| Factors | Benefits |

|---|---|

| Regular inspection | Early issue detection |

| Cleaning | Prevention of blockages |

| Electrode alignment | Efficient sparking |

| Component replacement | Improved performance |

Understanding how to clean and maintain your gas appliances’ ignition systems is essential, but there may be instances where professional assistance for ignition system repairs becomes necessary. Let us now explore this aspect in more detail.

Professional Assistance for Ignition System Repairs

Having discussed the steps to clean and maintain the ignition system, it is important to recognize that there may be instances where professional assistance becomes necessary. While routine maintenance can often address minor issues, certain situations demand expertise beyond what a typical homeowner possesses.

Example:

Consider a hypothetical scenario where an individual attempts to clean their gas stove’s ignition system but inadvertently damages some components in the process. Despite following all recommended guidelines, they find themselves unable to restore functionality. In such cases, seeking professional help would be prudent to prevent further damage and ensure safe operation.

Professional assistance offers several benefits when it comes to ignition system repairs. Here are some key reasons why engaging experts should be considered:

- Expertise: Trained professionals possess specialized knowledge about different types of ignition systems used in gas appliances, boilers, and stoves. Their training enables them to accurately diagnose problems and implement appropriate solutions.

- Safety: Gas-related repairs require careful handling due to potential risks involved. Professionals adhere to strict safety protocols while working with ignition systems, minimizing the likelihood of accidents or mishaps.

- Time-saving: Ignition system repairs involve intricate procedures that may be time-consuming for individuals without experience. Hiring professionals ensures efficient resolution of issues within a reasonable timeframe.

- Long-term cost-effectiveness: Attempting DIY repairs without adequate knowledge may exacerbate existing problems or cause new ones, leading to increased expenses down the line. Engaging professionals helps avoid costly mistakes and ensures effective repair work.

To emphasize these points further, let us consider a comparison between attempting DIY repairs versus hiring professional assistance:

| Aspect | DIY Repairs | Professional Assistance |

|---|---|---|

| Expertise | Limited understanding | Specialized technical knowledge |

| Safety | Potential hazards if mishandled | Adherence to safety regulations |

| Efficiency | Time-consuming process | Prompt resolution of issues |

| Cost | Risk of costly mistakes | Long-term cost-effectiveness |

In summary, while routine maintenance can address many ignition system issues, there are instances where professional assistance becomes essential. Trained experts provide the necessary expertise, adhere to safety protocols, save time, and offer long-term cost-effectiveness. By considering these aspects and conducting a comparative analysis, individuals can make informed decisions regarding their ignition system repairs.

Please let me know if there is anything else I can assist you with!

Atlanti Gaz

Atlanti Gaz