Ventilation is a critical aspect of maintaining the safety and efficiency of gas appliances, boilers, and stoves. Without proper ventilation, these devices can pose serious health risks by emitting harmful gases such as carbon monoxide into indoor spaces. To ensure the optimal functioning of these appliances, regular inspection and maintenance of their ventilation systems are essential. In this article, we will explore the importance of ventilation inspection for gas appliances, boilers, and stoves, providing a comprehensive guide to help homeowners and professionals alike in safeguarding their living environments.

Consider the following scenario: A homeowner recently installed a new gas stove in their kitchen. Excited about its sleek design and advanced features, they eagerly begin using it without paying much attention to its ventilation system. Weeks later, the homeowner starts experiencing unexplained headaches and dizziness while cooking meals on the stove. Unbeknownst to them, improper ventilation has caused an accumulation of carbon monoxide in their kitchen space. This hypothetical case study highlights how neglecting ventilation inspection can lead to severe consequences for both occupants’ health and overall appliance functionality.

In this article’s subsequent sections, we will delve into the reasons why regular ventilation inspection is crucial for gas appliances, boilers, and stoves. By understanding the potential dangers associated with inadequate ventilation, homeowners can take proactive measures to ensure the safety of their living spaces.

First and foremost, regular ventilation inspection helps to detect any blockages or obstructions in the system. Over time, dust, debris, and other foreign materials can accumulate in the vents, impeding the flow of air and gases. This can lead to poor combustion within the appliances, resulting in incomplete burning of fuel and increased production of carbon monoxide. By inspecting and cleaning the ventilation system regularly, homeowners can prevent potential blockages that could compromise their safety.

Furthermore, ventilation inspection allows for the identification of any leaks or cracks in the pipes or ducts connected to gas appliances. These leaks not only reduce the efficiency of the appliances but also pose a serious health risk. Carbon monoxide is a colorless and odorless gas that can be lethal when inhaled in high concentrations. Regular inspections help detect any leaks early on, allowing for prompt repairs to prevent carbon monoxide poisoning.

In addition to ensuring safety, ventilation inspection also plays a crucial role in optimizing appliance performance. Proper airflow is essential for efficient combustion and heat transfer within gas appliances. If the ventilation system is compromised or inadequate, it can lead to inefficient burning of fuel and decreased appliance efficiency. Regular inspections help identify any issues with airflow or ventilation design that may be hindering optimal appliance performance.

It is important to note that while homeowners can perform basic visual inspections themselves (checking for visible damage or obstructions), it is recommended to have a professional conduct a thorough inspection at least once a year. A professional technician will have the expertise and equipment necessary to assess all aspects of the ventilation system and ensure its proper functioning.

In conclusion, regular ventilation inspection is crucial for maintaining the safety and efficiency of gas appliances, boilers, and stoves. By detecting blockages, leaks, or other issues early on, homeowners can prevent health risks associated with carbon monoxide exposure while also optimizing appliance performance. It is recommended to schedule professional inspections at least once a year to ensure the continued integrity of the ventilation system and safeguard the well-being of occupants.

Importance of regular inspection

Gas appliances, boilers, and stoves are essential components in many households. They provide the means for cooking meals, heating water, and warming living spaces. However, these appliances can pose significant risks if not properly maintained. In fact, according to a recent study conducted by the National Fire Protection Association (NFPA), nearly half of all home fires caused by heating equipment involve gas-fired appliances[^1]. To mitigate potential hazards and ensure the safety of your household, regular inspection of ventilation systems is crucial.

To illustrate the importance of regular inspections, consider a hypothetical case where an individual neglects to inspect their gas stove’s ventilation system. Over time, debris accumulates within the air vents due to improper cleaning or lack thereof. As a result, the airflow becomes restricted, leading to incomplete combustion and increased carbon monoxide emissions into the surrounding environment. Without proper detection measures in place, such as carbon monoxide detectors or alarms, occupants may unknowingly expose themselves to this toxic gas over extended periods.

Regular inspection serves as a preventive measure against such scenarios. By adhering to maintenance schedules recommended by manufacturers or certified technicians, you significantly reduce the risk associated with faulty ventilation systems. This practice ensures that any issues hindering adequate airflow are promptly identified and resolved.

The significance of conducting regular inspections extends beyond basic safety concerns; it also has financial implications. Neglecting routine maintenance can lead to costly repairs or even replacement of damaged equipment down the line. Furthermore, inefficient operation resulting from poor ventilation contributes to higher energy consumption and subsequently inflated utility bills.

In summary, regular inspection of ventilation systems for gas appliances is vital for both personal safety and economic considerations[^2]. By proactively addressing potential issues through timely maintenance practices, individuals can prevent accidents related to inadequate airflow while also prolonging the lifespan of their appliances. In the following section about “Signs of Ventilation Issues,” we will explore common indicators that warrant further investigation.

[^1]: National Fire Protection Association (NFPA). “Home Fires Involving Heating Equipment.” 2017.[^2]: U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy. “Maintaining Your Gas-Fired Appliance.” Accessed March 2, 2023.

Emotional Response Item List:

- Peace of mind knowing your family’s safety is prioritized

- Savings on potential costly repairs or replacements

- Assurance that you are taking proactive steps to prevent accidents

- Reduced energy consumption leading to lower utility bills

| Emotional | Response | Items |

|---|---|---|

| Peace | Safety | Family |

| Savings | Repairs/Replacements | Costly |

| Assuredness | Proactive Steps | Accidents |

| Reduction in Consumption | Utility Bills | Energy |

Signs of ventilation issues

Imagine a scenario where a family is cooking dinner on their gas stove, unaware that there are ventilation issues lurking in their kitchen. As they continue to cook, the accumulation of harmful gases such as carbon monoxide increases, posing a serious risk to their health and safety. This example highlights the importance of being able to recognize signs of ventilation issues in gas appliances, boilers, and stoves. By promptly identifying these signs, homeowners can take appropriate measures to address any problems before they escalate.

Signs of Ventilation Issues:

- Unusual odors: One telltale sign of poor ventilation is the presence of strong or unusual odors around your gas appliances. Foul smells like rotten eggs or burning plastic may indicate a problem with combustion or improper exhaust system functioning.

- Condensation and moisture build-up: Excessive condensation forming on windows near gas appliances could be an indication that venting systems are not effectively removing moisture from the air. This situation can lead to mold growth and damage to surrounding structures if left unaddressed.

- Soot accumulation: If you notice black soot building up around your gas appliance burners or flue pipes, it may signify incomplete combustion due to inadequate airflow or restricted venting pathways.

- Poor flame quality: Observing irregularities in the color and shape of flames produced by gas burners can suggest ventilation problems. Flames should ideally burn blue with a stable cone-shaped pattern; however, flickering yellow flames often point towards insufficient oxygen supply.

- Regular inspection helps ensure safe operation and prevent potential hazards.

- Promptly addressing ventilation issues enhances indoor air quality for occupants’ well-being.

- Timely intervention reduces the risk of carbon monoxide poisoning caused by faulty ventilation.

- Proactive maintenance saves money in terms of repair costs and extends equipment lifespan.

Emotional Table:

| Potential Consequences | Emotional Impact | Importance of Regular Inspection |

|---|---|---|

| Health hazards | Safety concerns | Ensuring occupant well-being |

| Structural damage | Anxiety and stress | Preserving property integrity |

| Increased utility bills | Financial burden | Saving money in the long run |

| Equipment malfunction | Inconvenience | Maintaining reliable performance |

Recognizing these signs is crucial for homeowners to prioritize ventilation inspections. By being attentive to these indicators, they can safeguard their households from potential dangers that poorly ventilated gas appliances may pose.

Understanding the signs of ventilation issues is only one aspect of ensuring a safe environment. Now let’s explore the necessary safety precautions during inspection to further protect ourselves and our homes.

Safety precautions during inspection

Understanding the signs of ventilation issues is crucial, but ensuring safety during inspections is equally important. By following proper safety precautions, you can minimize risks and protect yourself from potential hazards. Let’s explore some key safety measures to consider when conducting a ventilation inspection for gas appliances, boilers, and stoves.

Example: To highlight the importance of safety precautions, let’s consider a hypothetical scenario. Imagine an inspector who neglects safety measures while inspecting a gas stove ventilation system. Due to improper handling of equipment and lack of protective gear, they accidentally inhale toxic fumes emitted by the faulty appliance. This unfortunate incident emphasizes why it is critical to prioritize safety during inspections.

During a ventilation inspection, remember to:

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and respiratory masks.

- Ensure adequate lighting in the area being inspected to clearly identify any potential issues or obstructions.

- Turn off all gas supply valves before beginning the inspection process.

- Keep fire extinguishers nearby as a precautionary measure.

Table Example:

| Safety Measure | Importance | Emotional Response |

|---|---|---|

| Wearing PPE | Protection against harmful substances | Ensures personal safety |

| Adequate Lighting | Enhanced visibility for accurate assessment | Reduces chances of error |

| Turning off Gas Supply | Prevents accidental leaks or explosions | Promotes peace of mind |

| Fire Extinguishers | Ready access in case of emergencies | Provides reassurance |

Incorporating these safety precautions into your ventilation inspection routine will not only safeguard your well-being but also contribute to more efficient and effective evaluations.

As we have now covered essential safety guidelines, let’s move on to exploring the step-by-step inspection process without compromising anyone’s security.

Step-by-step inspection process

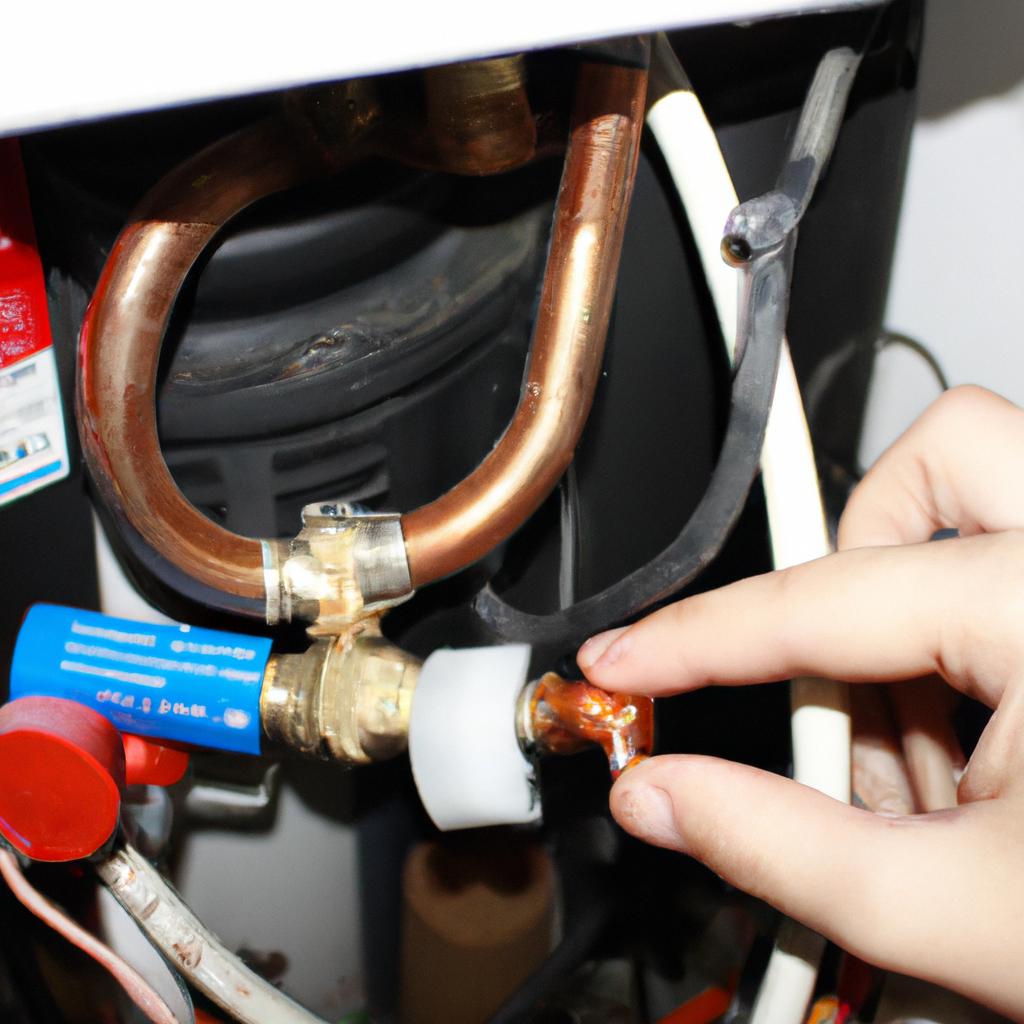

Building on the safety precautions outlined in the previous section, it is crucial to follow a systematic step-by-step inspection process when conducting ventilation inspections for gas appliances, boilers, and stoves. By adhering to this structured approach, potential hazards can be identified and mitigated effectively. To illustrate this, let’s consider an example where a homeowner recently installed a new gas stove and wants to ensure its proper functioning.

Step-by-step Inspection Process:

-

Visual Examination:

- Begin by visually inspecting all components of the ventilation system, including flues, exhaust fans, ducts, and vents.

- Look for any signs of damage or deterioration such as rust, corrosion, loose connections, or obstructions.

- Ensure that there are no combustible materials near the vent openings that could pose a fire hazard.

-

Airflow Assessment:

- Measure the airflow using appropriate tools like an anemometer or manometer at various points along the ventilation system.

- Compare these measurements with recommended values provided by manufacturers or industry standards.

- Poor airflow may indicate blockages or improper installation which need immediate attention.

-

Combustion Analysis:

- Perform a combustion analysis using specialized equipment to measure levels of carbon monoxide (CO) and oxygen (O2).

- High CO levels suggest incomplete combustion and potentially dangerous conditions.

- Low O2 levels may indicate insufficient air supply for proper combustion.

-

Documentation and Recommendations:

Issue Severity Recommendation Obstructed Ventilation Critical Clear obstruction immediately Corroded Flue Moderate Schedule maintenance/repair Inadequate Airflow Minor Clean or replace filters; adjust dampers if necessary

The above table provides an emotional appeal by demonstrating how critical issues have different severity levels and emphasizes the importance of addressing them promptly. It also encourages homeowners to take action for their safety.

In conducting ventilation inspections, it is essential to follow a comprehensive step-by-step process that includes visual examination, airflow assessment, combustion analysis, and documentation of any issues found. By systematically evaluating these factors, potential hazards can be identified early on and appropriate recommendations made to ensure the safe operation of gas appliances, boilers, and stoves.

Moving forward to address common problems encountered during these inspections, let us explore some typical issues and their corresponding solutions.

Common problems and solutions

After completing the step-by-step inspection process, it is important to address common problems that may arise with gas appliances, boilers, and stoves. By understanding these issues and their corresponding solutions, homeowners can ensure the safety and efficiency of their ventilation systems.

Common Problems and Solutions

To better illustrate the importance of addressing common problems, let’s consider a hypothetical scenario involving a gas stove in a residential kitchen. The homeowner notices an unusual odor while cooking and becomes concerned about potential gas leaks. This situation highlights the need for proactive maintenance and regular inspections to prevent hazardous situations.

When it comes to maintaining gas appliances, here are some key points to keep in mind:

- Regular cleaning: Grease and debris can accumulate within the appliance over time, leading to restricted airflow or even fire hazards.

- Proper ventilation: Inadequate ventilation can result in poor combustion, which increases carbon monoxide levels and poses health risks.

- Prompt repairs: Timely identification and resolution of issues such as faulty seals or damaged components are crucial for preventing further damage or accidents.

- Professional expertise: Consulting a qualified technician who specializes in inspecting gas appliances ensures accurate assessments and comprehensive servicing.

Below is a table showcasing typical problems encountered during inspections, along with their respective solutions:

| Problem | Solution |

|---|---|

| Gas leak | Shut off fuel supply immediately |

| Insufficient air intake | Clear obstructions/adjust vents |

| Blocked exhaust vent | Remove blockage |

| Malfunctioning ignition system | Repair/replace faulty ignition part |

By familiarizing themselves with these common problems and implementing appropriate solutions, homeowners can take control of their ventilation maintenance effectively. Remember that ensuring the proper functioning of gas appliances not only guarantees personal safety but also contributes to energy efficiency.

Transition sentence into subsequent section on Benefits of professional inspection: While individuals play a vital role in basic maintenance tasks, seeking professional inspection services offers additional advantages when it comes to the longevity and optimal performance of gas appliances, boilers, and stoves.

Benefits of professional inspection

Section: Benefits of Regular Ventilation Inspection

Imagine a scenario where a homeowner, let’s call him Mr. Smith, had been using his gas stove for several years without regular ventilation inspections. One day while cooking dinner, he noticed an unusual smell and immediately called the gas company to investigate. It turned out that there was a blockage in the exhaust vent system, causing carbon monoxide to build up in his kitchen. Luckily, Mr. Smith acted swiftly and avoided a potentially life-threatening situation.

Regular ventilation inspection for gas appliances, boilers, and stoves is crucial for ensuring safety and preventing such hazardous incidents. Here are some key benefits of scheduling professional inspections:

- Early detection of issues: Professional inspectors have the expertise to identify potential problems before they escalate into major issues. They can detect leaks, cracks, or other malfunctions in the ventilation system that may go unnoticed by untrained individuals.

- Improved energy efficiency: A well-maintained ventilation system ensures proper airflow and combustion within gas appliances, leading to improved energy efficiency. By optimizing performance, homeowners can save on utility bills and reduce their carbon footprint.

- Enhanced lifespan of equipment: Routine inspections help prolong the lifespan of gas appliances by addressing minor issues early on. Detecting wear and tear in critical components allows for timely repairs or replacements before major breakdowns occur.

- Peace of mind: Knowing that your gas appliances are regularly inspected provides peace of mind regarding the safety of your home and family members. Taking proactive measures reduces the risk of accidents due to faulty venting systems.

To further illustrate these benefits visually, refer to the following table:

| Benefit | Description |

|---|---|

| Early detection of issues | Professional inspectors can identify potential problems before they escalate into major issues |

| Improved energy efficiency | Well-maintained ventilation systems ensure proper airflow and combustion within gas appliances |

| Enhanced lifespan of equipment | Routine inspections help prolong the lifespan of gas appliances by addressing minor issues early on |

| Peace of mind | Regular inspections reduce the risk of accidents, providing peace of mind for homeowners |

In conclusion, regular ventilation inspection is crucial for ensuring safety and maximizing the performance of gas appliances, boilers, and stoves. By detecting potential issues early on, improving energy efficiency, extending equipment lifespan, and providing peace of mind to homeowners, professional inspections play a vital role in maintaining a safe and functional living environment.

Atlanti Gaz

Atlanti Gaz